We advise you

gladly to your

Production request

Call now

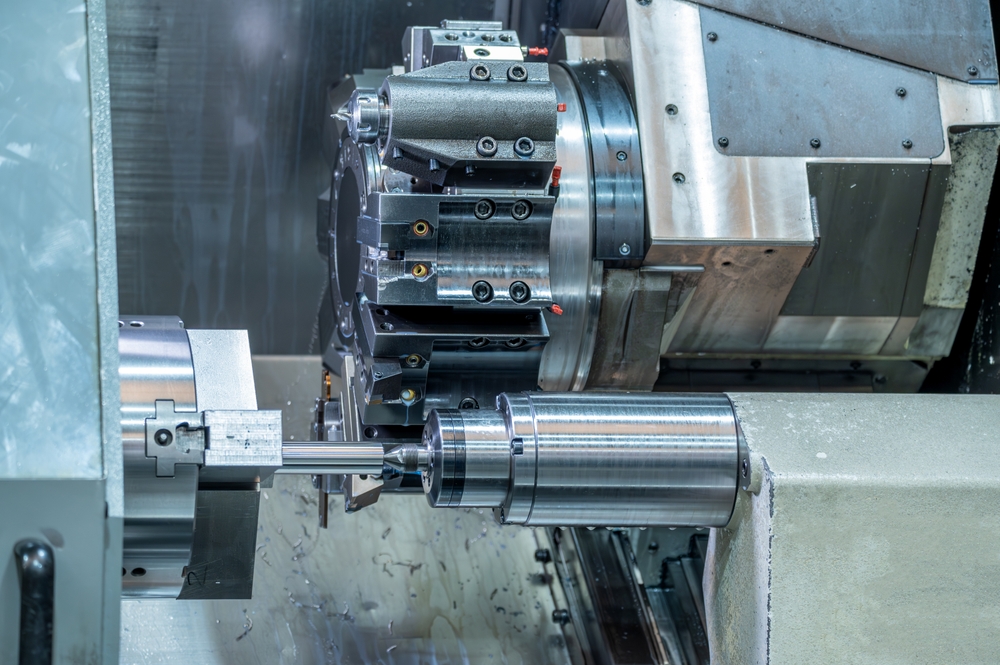

Turning

Turning is a central manufacturing process at FGW and enables the precise production of rotationally symmetrical components. Our turning technology is suitable for both simple parts and sophisticated geometries, which can be realized through combined turning and milling.

We process a wide variety of materials - from steel and stainless steel to aluminum and engineering plastics - and manufacture in small to medium quantities. Thanks to our equipment with multi-axis machines, even more complex work steps can be carried out efficiently in a single pass.

Thanks to many years of experience, well-established processes and technical diligence, we guarantee consistent quality, high repeat accuracy and cost-effective production - even for components with demanding tolerances.

Your advantages with FGW

What are the maximum dimensions that can be realized when turning?

We machine workpieces up to approx. 600 mm in diameter and 850 mm in length - depending on the component geometry and clamping technology.

Which materials can be turned?

The materials processed include structural steel, stainless steel, aluminum, brass and engineering plastics - depending on requirements.

Can turned-milled components also be manufactured?

Yes, with our turn-mill center we can produce complex components with several processing steps in a single clamping operation - efficiently and precisely.