We advise you

gladly to your

Production request

Call now

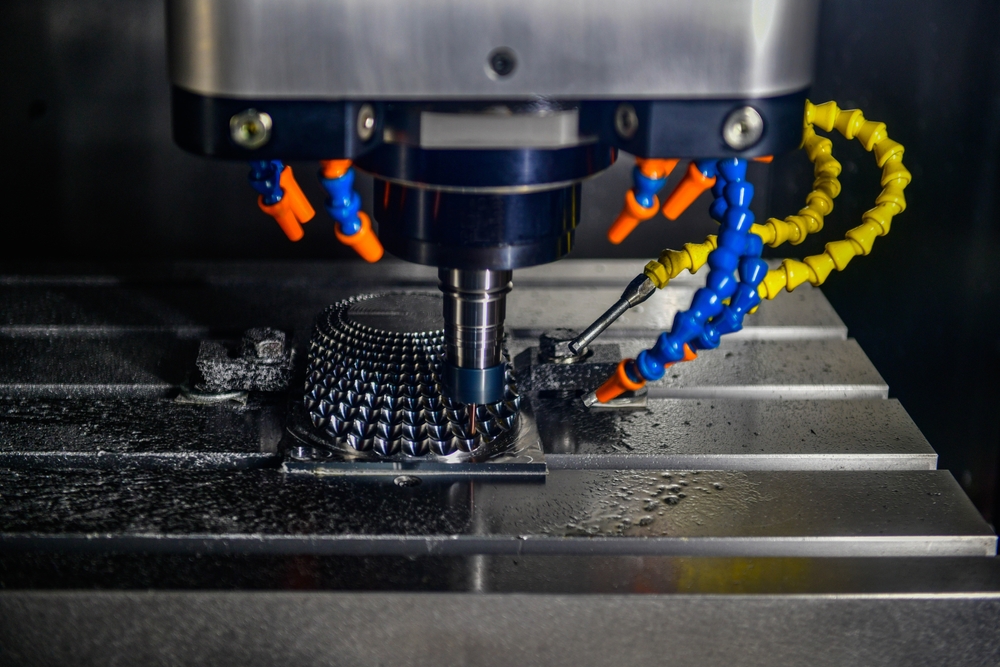

Milling (3-axis, 5-axis)

Milling has been one of the core competencies of FGW Sachsen GmbH for decades. With several 3- and 5-axis machining centers, we machine a wide variety of workpieces - from simple flat parts to complex geometries in small to medium quantities.

Thanks to our many years of experience, a practice-oriented approach and carefully maintained machines, we are able to manufacture both individual parts and series parts economically and reliably.

Whether it's the precise machining of aluminum profiles, steel blocks or plastic materials - we offer you reliable implementation with a focus on dimensional accuracy and function. Our team uses internal measuring technology to check every component for compliance with your specifications.

Your advantages with FGW

Which materials can be milled?

We generally process metals such as aluminum, steel, stainless steel, brass and copper. Plastics and non-ferrous metals are also possible - depending on the requirements and area of application.

What is the difference between 3-axis and 5-axis milling?

With 3-axis milling, machining takes place along the X, Y and Z axes. 5-axis machines also allow the tool or workpiece to be swiveled, enabling complex geometries and multiple sides to be machined in a single operation.

What tolerances can be maintained during milling?

The achievable tolerances depend on the component, material and machining process. As a rule, we operate in the range of ±0.01 mm to ±0.05 mm - absolutely sufficient for many technical applications.