We advise you

gladly to your

Production request

Call now

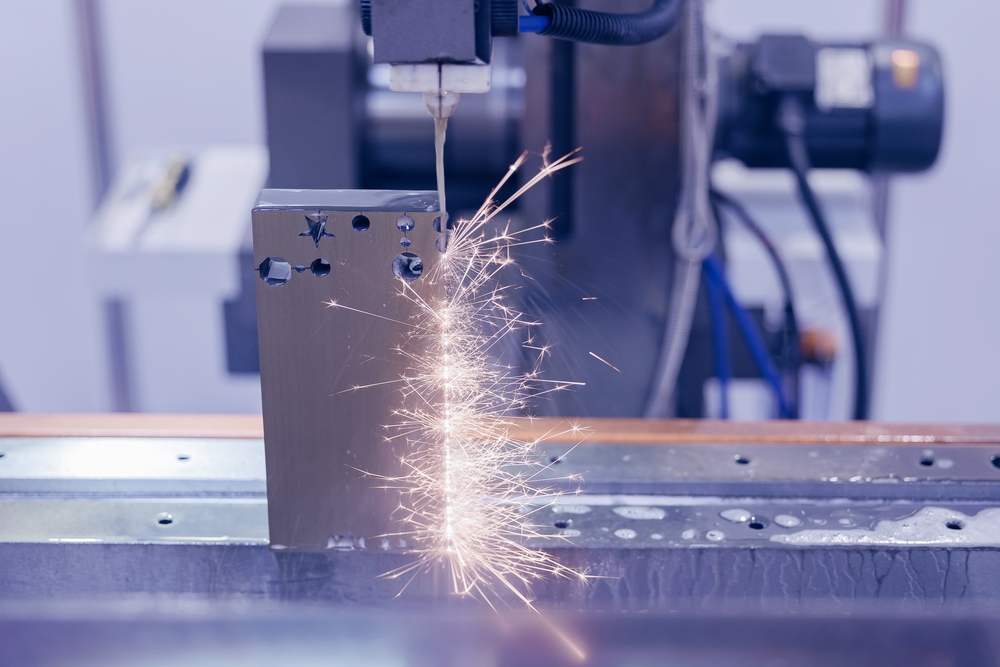

Wire erosion & die sinking

Spark erosion is a proven process for machining conductive materials - especially when conventional machining reaches its limits. At FGW, we offer both wire erosion and die-sinking erosion, enabling us to realize fine contours, tight inner radii and complex openings.

The process is particularly suitable for components with high demands on dimensional accuracy, edge quality and repeat accuracy - regardless of the hardness of the material. Our range of services also includes start hole drilling for preparing deep holes.

Wire-cut EDM is particularly suitable for slim, delicate cuts in hardened materials, while die-sinking EDM creates complex cavities or internal shapes. In combination with start hole drilling, we also enable sophisticated follow-up processes.

Your advantages with FGW

Which materials are suitable for eroding?

All electrically conductive materials - including tool steel, copper, carbide and aluminum alloys.

What is the difference between wire EDM and die sinking?

In wire EDM, the workpiece is contour-cut with a tensioned wire. In die-sinking EDM, a prefabricated electrode is used to erode a shape into the component.

What accuracies are possible?

Depending on the part geometry and machining length, we achieve tolerances in the range of ±0.005 mm - particularly relevant for fits or mold inserts.